FAQs on Colloidal Silver

Read the FAQs on Colloidal Silver here. These are typical questions we get asked regularly. If there is something you would like to know that is not answered here please do get in touch

Colloidal Silver is an antibacterial mineral solution containing silver ions & very small charged silver particles suspended in a dispersing medium (distilled water). As the particles have the same electrostatic charge (Zeta potential), they repel each other and this keeps them in uniform suspension throughout the medium. This is why it is called a colloid.

We make Amber Colloidal Silver which means it contains both ionic and particulate silver at an approximate ratio of 80% ionic & 20% particulate silver. It is important to understand that the silver particles are not dissolved but held in suspension by electrostatic charges. Without them, it would not be a colloid and not Colloidal Silver. Although silver ions are important, a 100% solution of silver ions is NOT Colloidal Silver.

Various names have been used to describe Colloidal Silver, such as Silver Sols. It is sometimes referred to as “Nano Silver” as the particles are in the range of 1 to 40 nm (Nanometres) or .001 to .04 um (Micrometres).

This is such an important question that we have written a whole page to answer this – in fact, we also very proudly can boast of a downloadable paper on the test we have, and continually undertake to bring you the best and safest Colloidal Silver possible. Please see our Testing & Analysis page.

We make the best Amber Colloidal Silver available on the market because we are the only manufacturer that has designed & built our own equipment and undergone rigorous independent product testing. We also control the whole process from start to finish. In fact, we spent over three years experimenting with different generator designs and the one we selected is far superior to any commercially available generator, for reasons that are listed in the next FAQ below.

More importantly, we have additional steps in our manufacturing process, to guarantee the final quality of the solution, which we believe are unique to us. We mature every batch produced, to ensure that it passes our quality checks. If a batch does not conform to the quality standards, we discard it.

Quality is very important to us, which is why we now have over 10 years of test data and believe you can only do this with a consistent quality tested product. We also publish these results to ensure honesty and transparency.

There are some good commercial generators on the market but they all have at least two flaws, which is why we use our own design.

- Most commercially available generators consist of an integrated unit containing an electrode assembly and a large plastic vessel with a tap at the bottom. After a production run, the solution is most likely bottled and shipped to the customer. As mentioned above, we have found that it takes several hours for the colloid to reach equilibrium (Maturity) and for its distinctive colour to develop. Only then can quality and stability be assured.

- The level of knowledge required to build a Colloidal Silver generator and understand the dynamics of the reaction is only at the Physics and Chemistry A-Level standard. Expertise in any manufacturing process is vitally important, especially to identify when things don’t go according to plan. We believe there is a high probability that owners of commercial generators have bought them because they lack the expertise to design and construct their own generator, which in turn suggests that they lack the expertise and understanding to ensure a safe, consistent quality product.

- We use laboratory grade borosilicate glass reaction vessels to manufacture and mature our Colloidal Silver. Commercial generators are generally made of plastic, which we feel is inferior. These may be small points but we believe they are important.

Because that’s all we need to do! Some suppliers state they are using dual and even triple pass distillation units. That means the water had been distilled two or three times, which is an incredible waste of energy. The reason we use a single pass system is because our naturally pure Somerset water is extremely soft to start with and that is all that it needs. As the energy consumption for distilling the water is the highest energy use in the entire process, it makes sense to ensure that it’s used wisely.

Pure water doesn’t conduct electricity, so if the water is too pure an additive will be required, which is totally undesirable.

After many years of only using glass, we have sourced a suitable plastic alternative to add to our range. Although we prefer glass, we realise good quality plastic is more than suitable for medium to high consumption user and even as a low-cost refill. We are all aware costs are always rising and this will help us to be able to supply our high-quality solution at a reasonable price.

Overview

PET (PolyEthylene Terephthalate) is a common food & pharmaceutical plastic which is cheap to produce & transport.

On the other hand, glass is heavy & fragile. That means extra packaging is required and it also has a higher energy cost both in the manufacture, recycling and because of the extra weight – increased postage costs.

So what is the real difference between glass & plastic bottles?

It’s the thickness of the wall of the bottle; that’s all. Actually, it’s quite simple. Everything that has a charge will eventually discharge. This is called leakage. Dielectric is the stuff between the + side and the – side, which could be anything such as air, water, glass, plastic etc. Both glass and plastic are excellent insulators BUT the wall of a glass bottle is many times thicker than a plastic bottle so its leakage is much less.

We’ve located a PET bottle manufacturer that makes a much thicker wall than normal bottles so our solution will keep twice as long! So we have now introduced this as our standard refill bottle. We will always use glass in our starter kits and glass will always be available but because of cost, it will be a premium range.

We conclude that glass is always the best for long term storage but plastic is excellent as a refill and for short term/high volume use.

If recycled correctly, plastic has a lower carbon cost & better for the environment.

Availability:

Because glass is fragile, we only supply up to 500ml in glass bottles. Plastic is available in 500 & 1000ml bottles.

99.9% silver is known as Fine Silver. There are several manufacturers that claim they use 99.99% and even 99.999% silver. We have found that anything purer than 99.9% (Known as .999 fine silver) is quite difficult to obtain, very expensive and actually, unnecessary.

In a 14 PPM solution, there are 999,986 parts of water to 14 parts of silver. The level of impurities in the water is therefore many times more important.

The Parts Per Million (PPM) issue is very confusing and we think, misleading

PPM is NOT an indicator of strength, its just an indicator of how much silver there is in the solution. It’s the particle size that’s important and we manufacture to get the particle size correct, which is why our solutions have such a good reputation.

Unfortunately, particle sizes increase with PPM so a higher PPM solution can have a much higher particle size due to a process called agglomeration. This is undesirable and should be avoided.

The honest answer is yes but it’s very easy to make bad Colloidal Silver & quite difficult to make good Colloidal Silver. Quality is VERY important to minimise the risk of argyria (Turning blue), especially as there’s a wealth of conflicting advice on the internet.

Water Quality:- Obtaining steam distilled water is virtually impossible. Most water is deionized, which makes a massive difference to the final product. We manufacture our own steam distilled water, as laboratory tests have shown that this produces the best particle size range. We experimented with filtration systems but they all produced larger particles size ranges. (Not good)

Generators:- Most commercial generators produce highly ionic silver water with very little (Less than 5%) colloidal particles, which is why we designed our own. The use of borosilicate glass and thermal stirring also helps to produce a higher quality solution. Maturation of the product is vital.

Testing:- Conductivity & PPM test meters give misleading results because the electrostatic charges interfere with the conductivity measurements. We calibrate our test instruments against laboratory results. At £400 per test, that can add up. Accreditations to an ISO/EC standard are usually in excess of £10,000, so we only do that periodically!

Knowledge:- It’s essential to have the basic scientific knowledge to determine when something isn’t quite right, as there’s a lot of unsafe practices being recommended & nothing is more important than your own safety!

We specialise in the manufacture of Traditional Amber Colloidal Silver, which contains silver nanoparticles. These nanoparticles absorb and scatter light with extraordinary efficiency and the yellow colour is caused by surface plasmon resonance (SPR). By controlling the particle size, shape, and the local refractive index near the particle surface, nanoparticle absorption and scattering properties can be finely tuned.

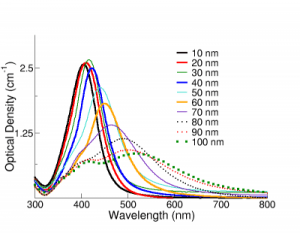

Smaller nanospheres primarily absorb light and have peaks near 400 nm, while larger spheres exhibit increased scattering and have peaks that broaden and shift towards longer wavelengths (known as red-shifting), so the yellow colour indicates the smaller particle sizes.

Please note that the colour only appears with concentrations over 5 PPM. It is easy to see this colour in large vessels but is less obvious in small quantities.

The yellow colour of the solution relates to unaggregated silver nanoparticles. Unaggregated silver nanoparticles will have a yellow colour in solution. If the particles aggregate, the solution with appears grey. The Yellow colour also relates to the stability of the solution, as it achieves a desired zeta potential and pH. Nanoparticles are either charge stabilized or sterically stabilized. For charge stabilized particles, the zeta potential is a measure of the particle’s stability. Typically, nanoparticles with zeta potentials greater than 20 mV or less than -20mV have sufficient electrostatic repulsion to remain stable in solution.”

Extinction (the sum of scattering and absorption) spectra of NanoXact silver nanoparticles with diameters ranging from 10 – 100 nm at mass concentrations of 0.02 mg/mL. BioPure nanoparticles have optical densities that are 50-times larger.)

Dried nanoparticles are aggregated and in nearly all cases cannot be re-dispersed as individual particles.

Most clear Colloidal Silver solutions do not contain any or a very small percentage of silver particles and tend to be ionic silver water solutions only.

Reaction vessels

This picture shows the amber colour in the large 3-litre reaction vessels. The colour is subtle in smaller amounts indicating the correct particle size range. The stronger the colour, the larger the particles which is NOT desirable.

Our Colloidal Silver has a minimum shelf life of two years, however once opened, we do recommend you use it withing 6 months. Glass bottles tend to preserve the delicate charges better over the long term & we know a client who had their Colloidal Silver for over 10 years!

Here’s why. The dissolved ionic silver content is very stable but the particulate silver is sensitive to external effects and the magnitude of these effects are proportional to the thickness of the wall of the bottle. Glass tends to be thicker and therefore preserves the delicate charges better than plastic but when disposed of correctly, plastic is lighter & takes less energy to recycle, so its better for the environment.

To look after your Colloidal Silver, don’t leave it in direct sunlight or allow it to get too warm. The best place to store you Colloidal Silver is in an old-fashioned pantry where the light is subdued and it is relatively cool.

No. Silver is a precious or Noble metal. Silver cannot be oxidized to toxic compounds like lead and mercury, which is why we use it for jewellery, cooking utensils, drinking vessels and many other uses where its safe antibacterial properties are required.

We use Feefo & Google Reviews for all of our reviews. Why? Because you have to be a verified customer to place a review which makes them all as genuine as possible. That’s very important for all of us.

Click here for our Google Reviews.

Please see our Terms & Conditions page which covers all these topics.

Plastic is a marvellous material but it’s causing major issues. Being cheaper to manufacture, it requires less protective packaging than glass and has a lower energy life cycle. Unfortunately, it doesn’t easily bio-degrade and if not recycled correctly, will pollute the environment. We are looking at all our packaging and are adjusting it in line with our plastic policy as follows:-

- All our standard packaging is now plastic free – We use paper flute instead of bubblewrap & crumpled paper as void fill.

- Plastic Bottles – These will continued to be supplied but we urge you to use your local recycling service to ensure correct disposal.

- Measure cups – They will only be supplied with Starter Kits but available as a separate product if needed.

- Packing Tape – We now use paper tape.

- We do , however, recycle plastic from suppliers so you may get some in your order. Please recyle this where possible.

We do not sell through Amazon Prime for several reasons.

- To be supplied by Amazon, we’d have to make shipments to Amazon’s fulfilment centre & they then ship it again to you. That’s double shipping and double the carbon cost. We think this is irresponsible.

- We manufacture daily & ship freshly made solutions directly to our customers. We estimate that the solution you receive is at its best and is no longer than a few days old. Unfortunately, products can hang around unsold in Amazon warehouses and your product may not be at its best.

- Amazon has strict packing guidelines, especially for glass, which increases unnecessary waste plastic in the environment. The costs of these additional packaging inflate the price. Our plastic-free packaging doesn’t pass Amazons tests. However, it does pass Royal Mails!

Our view? Amazon may be handy to use but it’s at the expense of our environment. We think this is one of the factors leading to climate change and NOT supplying through them is a small part of our strategy to be a responsible company.

We have worked with Trading Standards to ensure our product is advertised correctly and through blind testing, that our product is consistent with the its description.